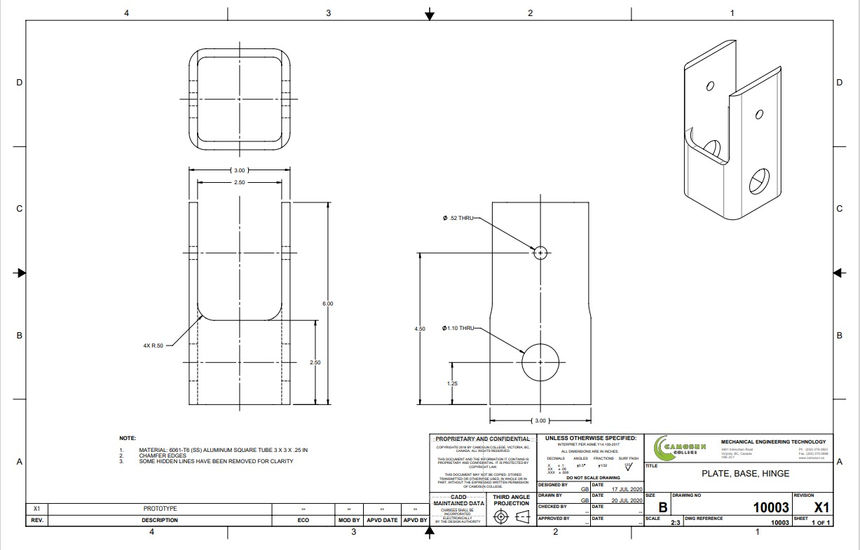

DEPLOYMENT STRUCTURE

SOLIDWORKS | CAD | DRAWINGS | MILL | LATHE

This deployment structure is Gillian's capstone project for the end of her Mechanical Engineering Technology Diploma. Gillian worked with a group of engineering students to provide a solution for the deployment of a DTS-12 Turbidity Sensor for their clients, Forest Technology Systems (FTS) and the CRD. The DTS-12 Turbidity sensor is used to measure the turbidity levels of water in the CRD watershed. Measuring the turbidity levels in water is crucial for quality assurance and process control of drinking water. The current design used resulted in inaccurate data collection due to device placement. The proposed solution is designed for accurate data collection, protection, manufacturing, and servicing for commercial use. The deployment device is a modular design that can be mounted onto various structures.

This project focused on detailed design, cost estimation (to remain within budget), manufacturing, project management, detailed reports, presentations, effective communication and scheduling meetings with the team and clients. As the documentation lead, Gillian took responsibility for accuracy and promptness of timesheets, reports, presentations, and engineering drawings shown in the photos above. All CAD models and engineering drawings were made using Solidworks and the parts were then machined using manual and CNC mills and lathes.

Note: EBOM not provided in order to maintain confidentiality with parts given by FTS.

WHERE

MECH 275 - COMPUTATIONAL MODELLING AND VIBRATIONS

WHEN

2020